In March 2018, the CEO, Office Manager, and Board of Directors of the EOCP had the opportunity to meet with key stakeholders in Yukon and visit an impressive water treatment facility.

Situated on the north shore of Marsh Lake in Yukon, Army Beach is a small recreational community comprised of a mix of summer-only residents and a growing number of year‐round residents. Residents previously obtained drinking water from a variety of sources such as commercial haulers out of Whitehorse, self‐haul, or directly from the lake. In 2006, the Yukon Government proposed development of a new water treatment plant and bulk water fill station at Army Beach to provide a local source of water to be distributed by commercial haulers. Engineering services for the design and construction of the intake, water treatment plant, and bulk water fill station were provided by Opus Engineering Consultants (Canada) Ltd (Opus).

Previous investigation of groundwater sources proved the lake water to be a more cost-efficient source to treat. Several intake and pump configurations were assessed. The intake line was installed deep below the frost line, using directional drilling methods, going out about 500 meters out into lake. Ultra‐filtration, or membrane filtration was selected for treatment and two GE ZBox package plants were installed. The facility, completed in 2009, also includes a bulk truck fill system, complete with an automated billing system.

- Why a new facility? The facility was to provide a public bulk potable water fill station and emergency fire truck fill point at the Army Beach subdivision and Marsh Lake Recreation Site. The station was intended to be used by commercial bulk truck haulers and residential users via a ‘blue jug fill point’ and a ‘pickup truck fill point’

- Why was this location chosen? The location was selected to be convenient to the Army Beach community as an alternative to hauling water from Whitehorse. It was also selected to permit fire trucks to re-fill as there is no satellite firehall in this area.

- Why was this technology selected? A groundwater investigation was unsuccessful in finding good quality water with sufficient yield, so the decision was made to use Marsh Lake as the water source. Ultrafiltration and chlorine disinfection using sodium hypochlorite, with contact time, was selected to meet the treatment requirements of Guidelines for Canadian Drinking Water Quality. The water treatment objectives were the following:

- 4-log (99.99%) reduction/inactivation of viruses

- 3-log (99.9%) reduction/inactivation of Giardia and Cryptosporidium

- 2 (dual) disinfection/treatment barriers

- <1 NTU turbidity

- 0 Fecal/Coli

- Water quality before and after: Generally, the quality of the water from Marsh Lake was very good, but as a surface water required a robust and effective treatment system to be safe to drink.

- Where did the funding come from? Federal and Yukon Governments.

- Highlights of the facility:

- The intake line was installed deep below the frost line, using directional drilling methods, to 500 m out into lake; a submersible pump was installed 25 m down the intake line, below the lake low water level, about 8 m below the ground surface; the intake pipe was brought to surface inside the water treatment plant.

- Simple slab on grade foundation construction with a pre-engineered steel building using pre-fabricated Zip panels for simple construction and high insulation values.

- Fully automated, with automatic shutdown for critical water quality parameters or equipment failures; online chlorine residual and treated water turbidity monitoring provided with plant shutdown for high turbidity or low chlorine residual.

- The system generates minimal backwash (back-pulse) water which is directed to a rock pit at the site.

- The facility also includes a truck fill system, complete with an automated billing system.

- Chlorine contact and water storage were provided inside the building using HDPE tanks, allowing operators to see and clean the tanks easily.

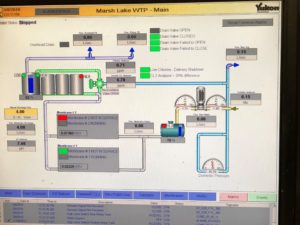

- A SCADA computer allows the operator to access the plant remotely via the internet to monitor the systems, check and acknowledge alarms, and change set points.

- Benefits of the facility: A convenient and safe source of drinking water for the local residents and recreational users of Marsh Lake, and a facility to supply bulk water to commercial suppliers and to fill fire trucks.

- Project Costs: $2,700,000 – Some additional advantages of this facility design from an Operator standpoint are that it produces very high-quality water with little downtime – as long as maintenance schedules are followed. While the overall system is somewhat complex for such a small plant, once the Operators became familiar with it, they found it to be robust and reliable.

by Carol Campbell P. Eng and Kalpna Solanki BSc MBA CPHI(C)

To see the full Operator Digest, click here.